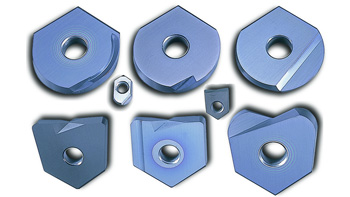

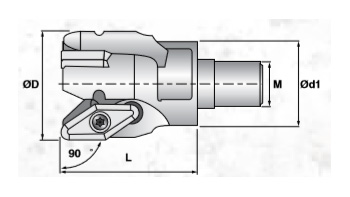

Millstar profile milling tools represent the latest in profile and contour milling technology, providing you with the competitive edge of shorter machining / lead times and the competitive advantages of higher machining accuracy and true contouring results.

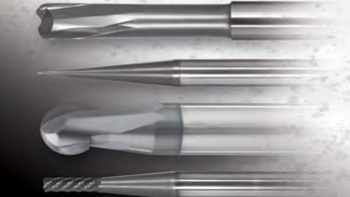

The best coatings among these are the most advanced, proprietary EXALONTM ALTiN based coating and Si based HSN coating which has demonstrated superior performance characteristics over an impressive list of world wide competitors in Die-Mold and Aerospace parts milling.

Millstar offers solutions to cut the toughest of materials like Titanium, Inconel and other HRSA materials.

Millstar inserts and Solid carbide tools can work at very high cutting speeds ranging from 250 meters/min up to 400+ meters/min in Die Mold Steels.

Millstar tools for HRSA materials can work at cutting speeds varying between 90 meters/min upto 180 meters/min which is an industry record.

Millstar also offers diamond coated and PCD tipped tools for Graphite machining which offers unparalleled performance at cuttings speeds in excess of 700 meters / min !